21 Jul The right fitting for your hydrogen (H2) application

Our valves can be used in the entire hydrogen process chain – from hydrogen production to to compression stations and filling stations. In doing so, we also address your specific application conditions in order to offer you the best technical and economic solution.

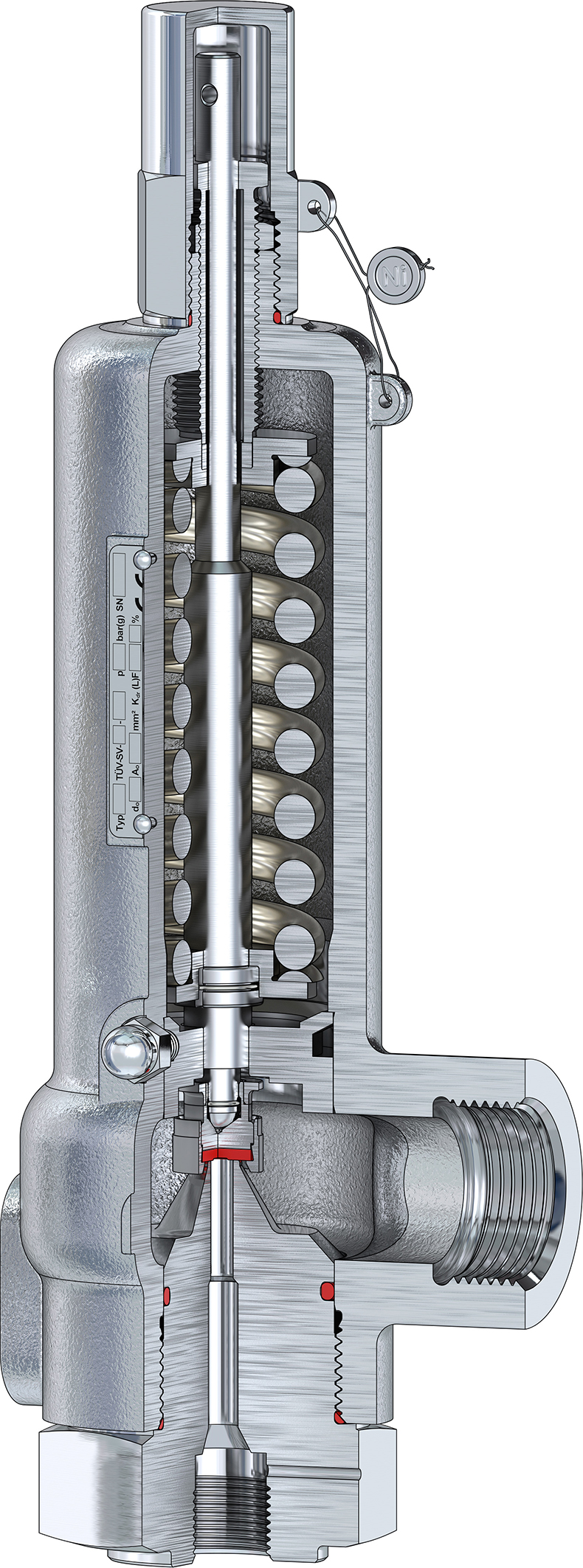

Type 21.2 Safety valve for up to 1100 bar(g) according to ISO4126-1

Material: Inlet body / spring hood

1.4571 / 1.4581

Connection Entry: Medium Pressure Cone + Thread Port Type 9M 13/16-16 UN

(alternative connectors, see data sheet)

Connection outlet: pipe thread ISO 228, socket G1 or NPT thread, socket 1 NPT

Cone seal: PEEK (alternative materials on request)

Flow media: Vapours, gases and liquids

Response pressure: 300 – 1100 bar(g) (liquid 250 barg)

Temperature range: -60°C to 100°C (depending on pressure up to 280°C possible)

This safety valve is a universally applicable valve for high pressures in many areas. Due to the low leak rate in the seat/cone area (max. 10-6 mbar l/s),

it is suitable for the use of volatile media (hydrogen).

Helium leak test certificates can be ordered at the same time

Approvals:

Examples:

Hydrogen production: in plant components

Storage: Pre-seal protection – Filling stations

Refuelling: Tank system protection